Choosing the right forklift mast plays a critical role in operational efficiency, workplace safety, and long-term equipment cost. Many buyers focus only on lift height, but real-world performance depends just as much on overhead clearance, free lift, and mast stability. This forklift mast selection guide explains how to evaluate these factors and choose the right mast type for modern warehouse and logistics operations.

1. Understanding Lift Height Requirements

Lift height is the vertical distance from the ground to the top of the forks when fully raised. It is the foundation of any forklift mast selection process. Defining the correct lift height ensures the forklift can reach the highest storage position without unnecessary cost or performance limitations.

Typical forklift mast lift height ranges and their applications include:

| Standard Lift Height | Typical Application Scene |

|---|---|

| 3–4 m (10–13 ft) | Workshop operations, truck loading and unloading, low-level racking |

| 4.5–5 m (15–16.5 ft) | Standard warehouse racking systems and distribution centers |

| 6 m+ (20 ft+) | High-bay storage and specialized warehousing environments |

Important note:

Forklift rated capacity is calculated using a standard load center, typically 24 inches or 600 mm. As lift height increases, allowable load capacity may decrease. Always consult the forklift load capacity chart when operating at higher lift heights.

2. Choosing Between 2-Stage and 3-Stage Forklift Masts

Among all forklift mast types, 2-stage and 3-stage masts are the most commonly used. The correct choice depends on the balance between required lift height and available overhead clearance.

2-Stage Forklift Mast (Duplex Mast)

A 2-stage mast consists of one outer mast section and one inner mast section.

Key characteristics include:

- Good forward visibility for the operator

- Simple and robust structural design

- Lower maintenance complexity

This mast type is best suited for operations with sufficient overhead clearance, such as open yards, loading docks, and high-ceiling facilities. A 2 stage forklift mast is often the most economical and durable option for general material handling tasks.

3-Stage Forklift Mast (Triplex Mast)

A 3-stage mast uses three nested mast sections to achieve higher lift height while maintaining a lower collapsed mast height.

Key characteristics include:

- High lift capability with reduced overall mast height

- Better suitability for low-clearance environments

- Greater flexibility for indoor warehouse operations

Most 3 stage forklift masts are equipped with forklift free lift, which allows the forks to rise without increasing the mast’s collapsed height. This feature is essential for safe operation inside shipping containers, trailers, and warehouses with low doorways.

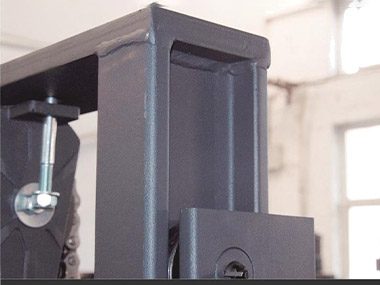

3. Engineering Factors That Affect Mast Stability and Durability

Beyond mast type and lift height, structural details have a significant impact on long-term safety and performance.

Key engineering considerations include:

- Mast overlap, which improves rigidity and reduces sway during high-lift operation

- Steel quality and channel thickness, which determine resistance to twisting and deformation

- Overall mast design, including roller systems and top mount construction

A well-designed mast with sufficient overlap and high-strength materials is especially important for heavy loads and frequent high-reach applications.

4. Forklift Mast Selection Checklist

Use this checklist to confirm the most suitable mast configuration for your operation:

- Measure the lowest overhead obstruction the forklift must pass under

- Identify the maximum stacking or racking height required

- Choose a 2-stage mast when overhead clearance is sufficient

- Choose a 3-stage mast with adequate free lift for low-clearance environments

- Consider load weight, load center, and operating frequency

5. Frequently Asked Questions About Forklift Mast Selection

1.What is free lift on a forklift mast?

Free lift is the vertical distance the forks can be raised without increasing the mast’s collapsed height. It allows safe lifting in low-clearance environments such as shipping containers, trailers, and warehouses with low doorways.

2.Is a 3-stage forklift mast better than a 2-stage mast?

Not always. A 3-stage mast is ideal when overhead clearance is limited and higher stacking is required. A 2-stage mast is often preferred in open environments because it offers better visibility, simpler maintenance, and lower overall cost.

3.How much free lift is needed for container operations?

For standard containers and trailers, a free lift of approximately 1,000–1,500 mm (40–60 inches) is commonly recommended. Exact requirements depend on container height, floor conditions, and load dimensions.

Need Expert Guidance on Forklift Mast Types?

Selecting the right forklift mast involves more than choosing a lift height. Overhead clearance, free lift requirements, load center, and warehouse layout all play an important role in safe and efficient operation.

Contact our material handling experts today for a free consultation, including mast height calculation, free lift recommendations, and forklift configuration advice tailored to your specific application. As a professional forklift and material handling equipment supplier, we support you from initial forklift mast selection through final configuration, helping you maximize productivity, safety, and long-term value.

Simply share your rack height, doorway clearance, or container usage scenario, and we will help you identify the most suitable mast configuration.

Contact Us Today!

📧 Email: info@lesougoods.com

📱 WhatsApp / WeChat: +86 185 3113 1986

We are always online and guarantee a response within 24 hours with a model recommendation and a clear shipping solution.

Get Quality Product Information

We offer rigorously selected forklift products, all equipment meets international quality standards.